Wet Scrubbers

Wet Scrubbers

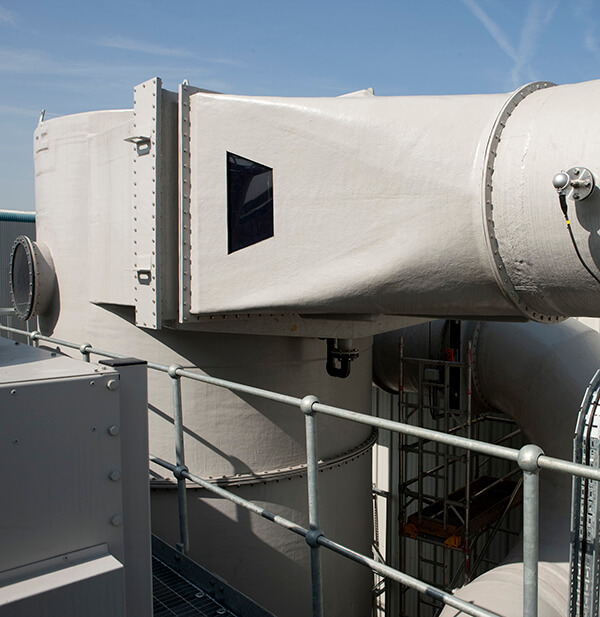

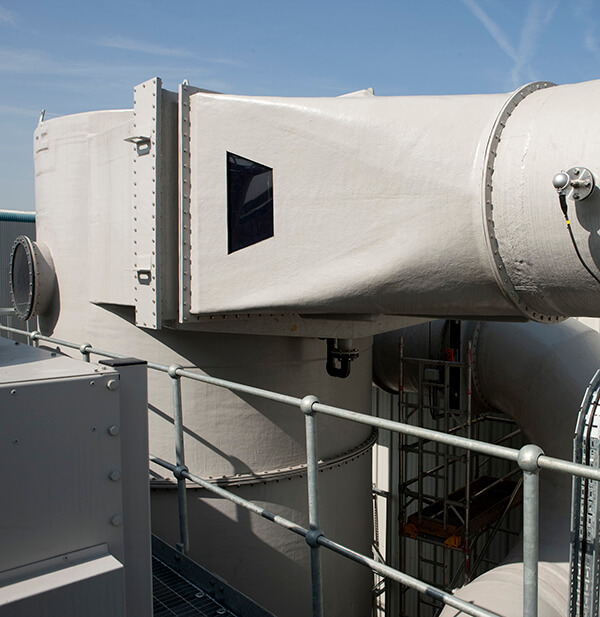

Chemical scrubbers are a highly efficient way to remove H2S odour and other soluble contaminants from an odorous airstream

- All ERG designs are bespoke and matched to the detailed requirements of the application specification

- ERG uses industry-standard random packing to optimise operating efficiency with system pressure drop and equipment size

- All packages carry a performance guarantee and are designed to provide robust operation at the lowest capital and operating costs

Our extensive design and operating experience enables us to optimise the system performance.

Design Parameters

- Flowrate ranges from 100 to 100,000 m3/hr per tower, multiple towers in parallel can be used for higher flowrates

- Odour loadings up to 1,000,000 ouE/m3 are common

- Soluble contaminants typically 50-200ppm average, and up to 1,000ppm peak

- Typical removal effciency 99.5%, up to 99.95% as required

- Vessel diameters from 200 to 3,800mm, heights typically up to 10m, or higher if the process requires it

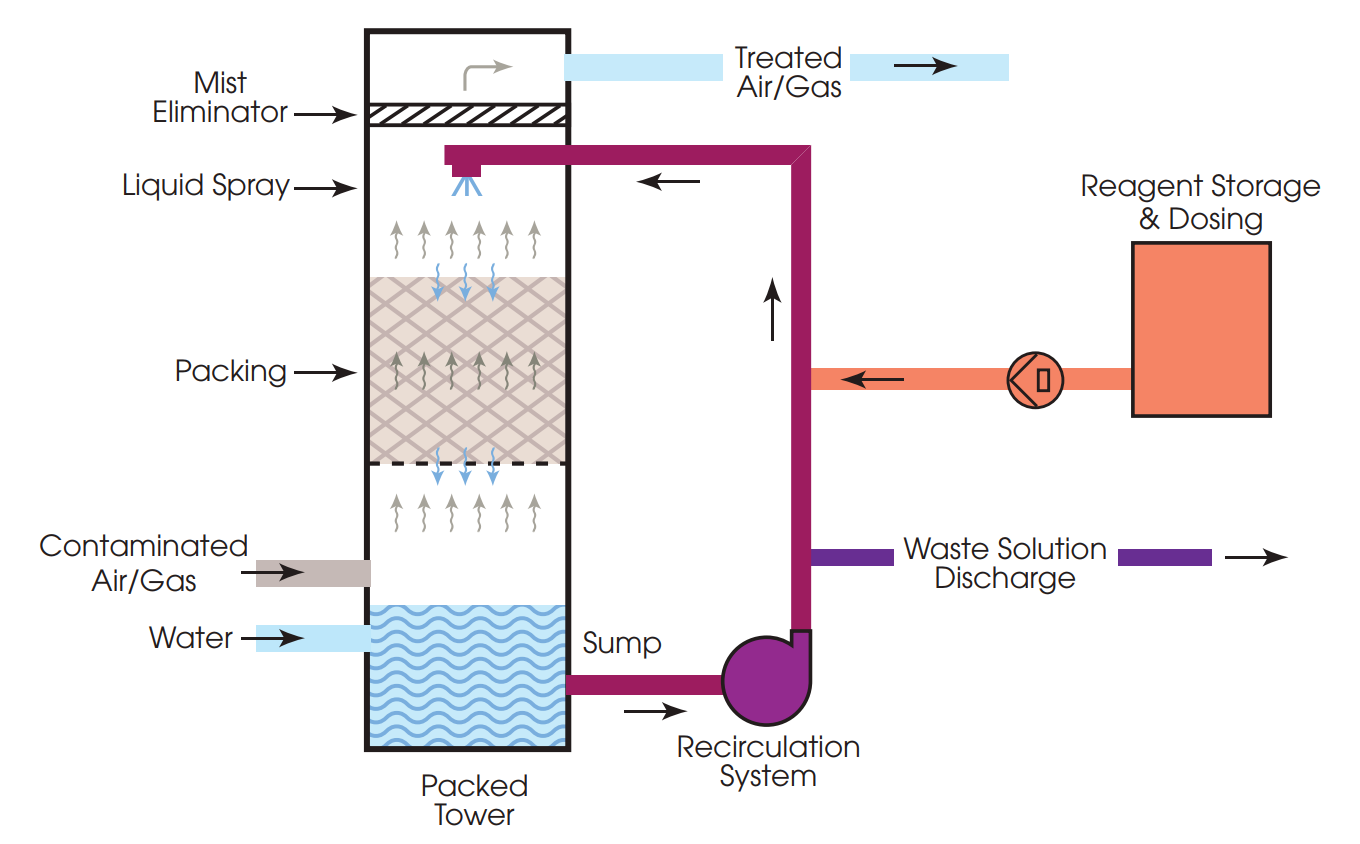

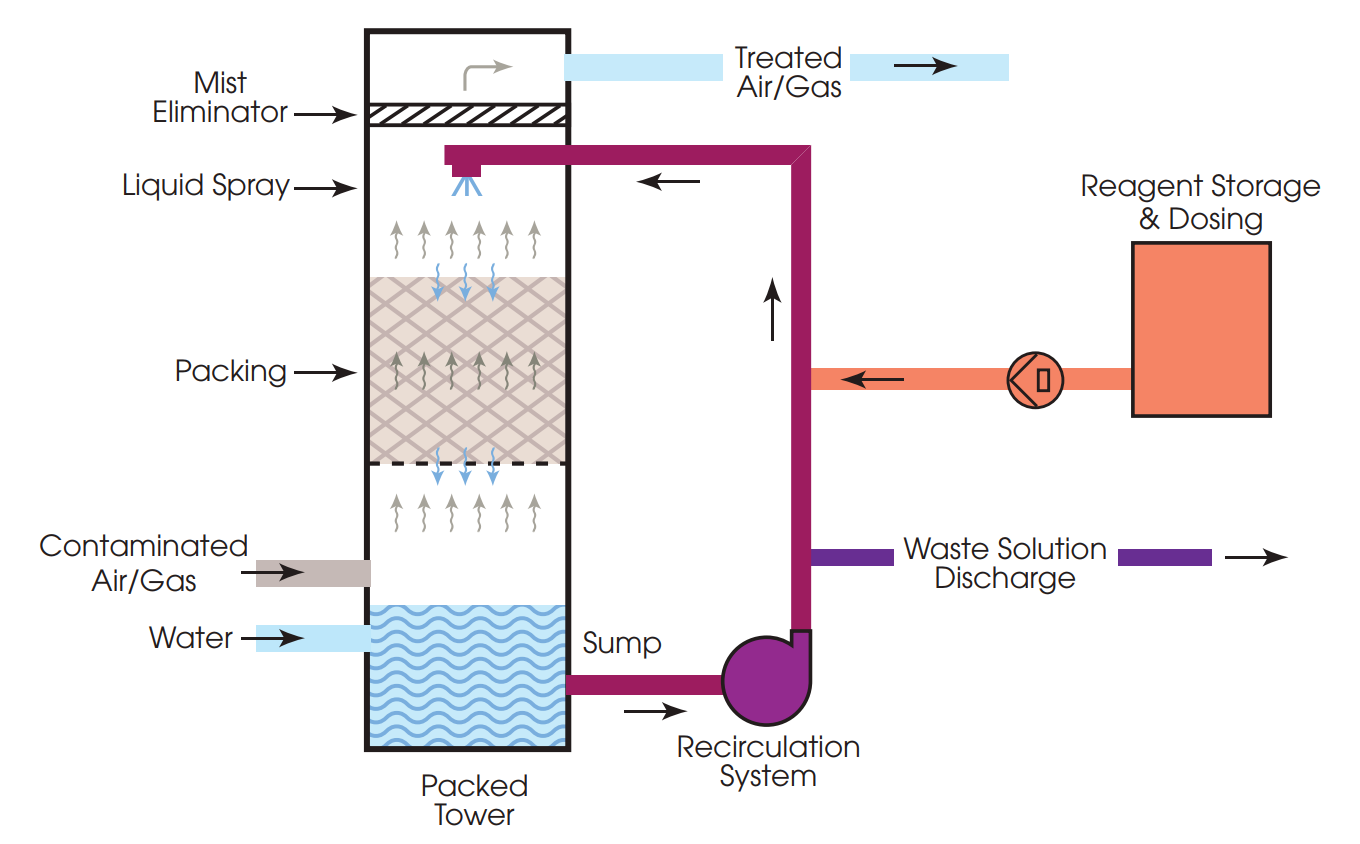

Diagram of typical chemical scrubber

Design Parameters

- Flowrate ranges from 100 to 100,000 m3/hr per tower, multiple towers in parallel can be used for higher flowrates

- Odour loadings up to 1,000,000 ouE/m3 are common

- Soluble contaminants typically 50-200ppm average, and up to 1,000ppm peak

- Typical removal effciency 99.5%, up to 99.95% as required

- Vessel diameters from 200 to 3,800mm, heights typically up to 10m, or higher if the process requires it

Diagram of typical chemical scrubber

Key Features

- Complete systems supplied including recirculation pump, pipework, fan, ductwork, access platform, instrumentation and control system – and may be integrated further with a carbon filter

- Commonly used packing types include Snowflake/AstraPAC and 1″, 1.5″ and 2″ Pall rings

- Recirculated liquor flowrate selected to minimise pump flow and energy consumption at optimal scrubbing performance

- Liquor distribution across packing using sprays or trough distributors depending on application

- Droplet elimination using chevron, impaction blade or woven mesh design to suit application – clean in place sprays available to assist with on-line maintenance

- Scrubber sump tank integrated into the packed column vessel

- Chemical dosing, water make-up and blowdown control to match specific performance requirements

- Instrumentation selection to give robust operation, high reliability and tight performance control

- Vessel designed as standard to BS EN 13121 or BS 4994

- Materials selection to suit contaminants and reaction chemistry: common materials include uPVC, PP, Derakane® GRP, Crystic® GRP

Key Features

- Complete systems supplied including recirculation pump, pipework, fan, ductwork, access platform, instrumentation and control system – and may be integrated further with a carbon filter

- Commonly used packing types include Snowflake/AstraPAC and 1″, 1.5″ and 2″ Pall rings

- Recirculated liquor flowrate selected to minimise pump flow and energy consumption at optimal scrubbing performance

- Liquor distribution across packing using sprays or trough distributors depending on application

- Droplet elimination using chevron, impaction blade or woven mesh design to suit application – clean in place sprays available to assist with on-line maintenance

- Scrubber sump tank integrated into the packed column vessel

- Chemical dosing, water make-up and blowdown control to match specific performance requirements

- Instrumentation selection to give robust operation, high reliability and tight performance control

- Vessel designed as standard to BS EN 13121 or BS 4994

- Materials selection to suit contaminants and reaction chemistry: common materials include uPVC, PP, Derakane® GRP, Crystic® GRP

UK office: +44 1403 290 000 Middle East office: +962 6515 9021 Email: info@ergapc.co.uk