Tray Towers

Tray towers are used for cleaning gas flows which are contaminated with both particulate and soluble noxious gases. Their unique design enables them to capture particulate >2 micron as well as soluble gases to high efficiencies of removal. ERG designs and manufactures each tray scrubber to meet your specific application and detailed requirements.Key Advantages of Tray Scrubbing Are:

- Multiple tray stages of scrubbing give excellent efficiencies of removal

- Highly effective at treating large gas flows at comparatively low capital cost

- Running costs are relatively low due to the low gas side pressure drop and the low liquor rates required

- Trays are self-cleaning, reliable and robust

- Trays types such as fixed valve design can be matched to suit the application

- Tray weir height can be adjusted to give enhanced capture of contamination and greater turn down if this is required

Design Parameters

- Flowrates from 2,000 to 100,000 m3/hr per tower, multiple cylindrical towers in parallel or rectangular cross-section for higher flowrates

- Removal of any soluble gaseous contaminant and soluble or insoluble particulate >2 micron

- Gaseous contaminant loadings typically from 100 to 10,000 mg/m3; particulate loadings typically up to 5,000 mg/m3

- Removal efficiencies typically 90-95% and up to 99% as required

- Vessel diameters from 600 to 3,800 mm; vessel heights typically up to 12 m

Key Features

- ERG supplies complete systems including recirculation pumps, pipework, fans, ductwork, access platform, instrumentation and control system. They can also be integrated with other ERG mass/heat transfer equipment (e.g. quench, venturi, packed tower, carbon filter, etc.) into a single air pollution control solution

- Trays used include simple perforated plates and impaction valve designs

- Adjustable weirs provide variable pressure drop and stage efficiency; under-tray sprays improve resistance to fouling

- Recirculated liquor flowrate selected to minimise pump flow and energy consumption at optimal scrubbing performance

- Droplet elimination using chevron, impaction blade or woven mesh design to suit application – clean-in-place sprays available to assist with on-line maintenance

- Scrubber sump tank integrated into the vessel – cone and sloping base designs are available to improve maintainability in solid-laden applications

- Chemical dosing, water make-up and blowdown control matched to the performance requirements

- Side-stream settler and dewatering of captured solids available if required

- Instrumentation selection to give robust operation, high reliability and tight performance control

- System control by stand-alone MCC/C&I panel or integrated DCS, with HART or Profibus protocols available as standard

- Vessels designed as standard to PD 5500 (metal) and BS EN 13121 or BS 4994 (plastic/GRP) with CE marking to PED as appropriate. Other design codes available as required

- Materials selection to suit contaminants and reaction chemistry: common materials include uPVC, PP, cPVC, derakane GRP, crystic GRP, 304SS, 316SS

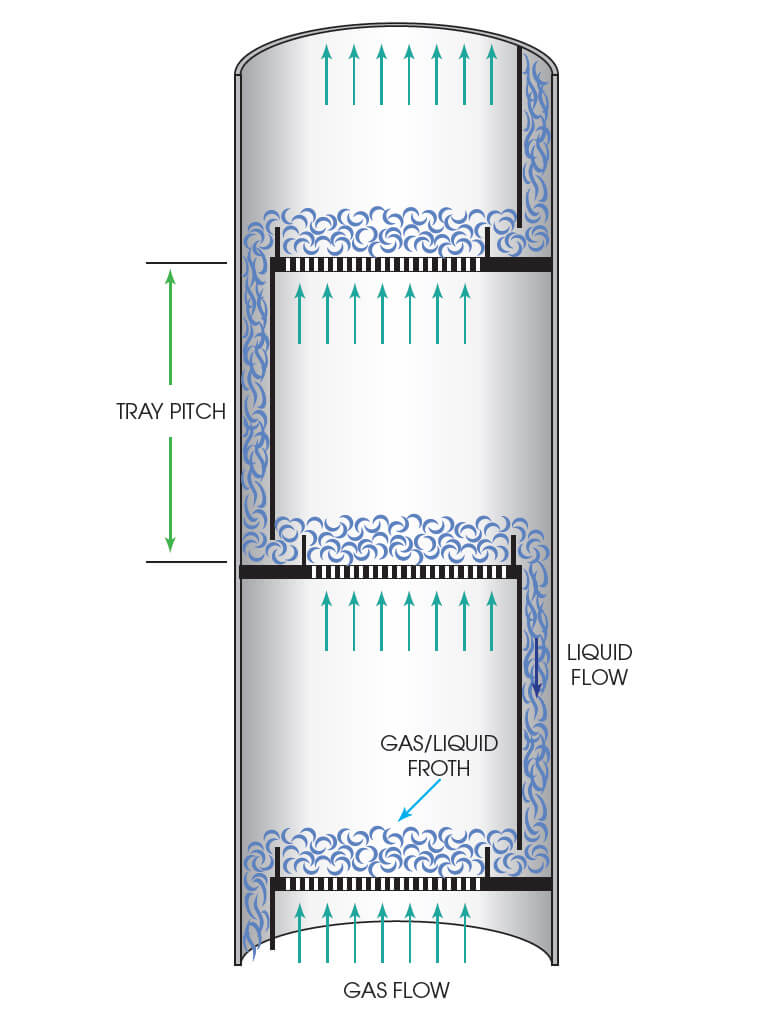

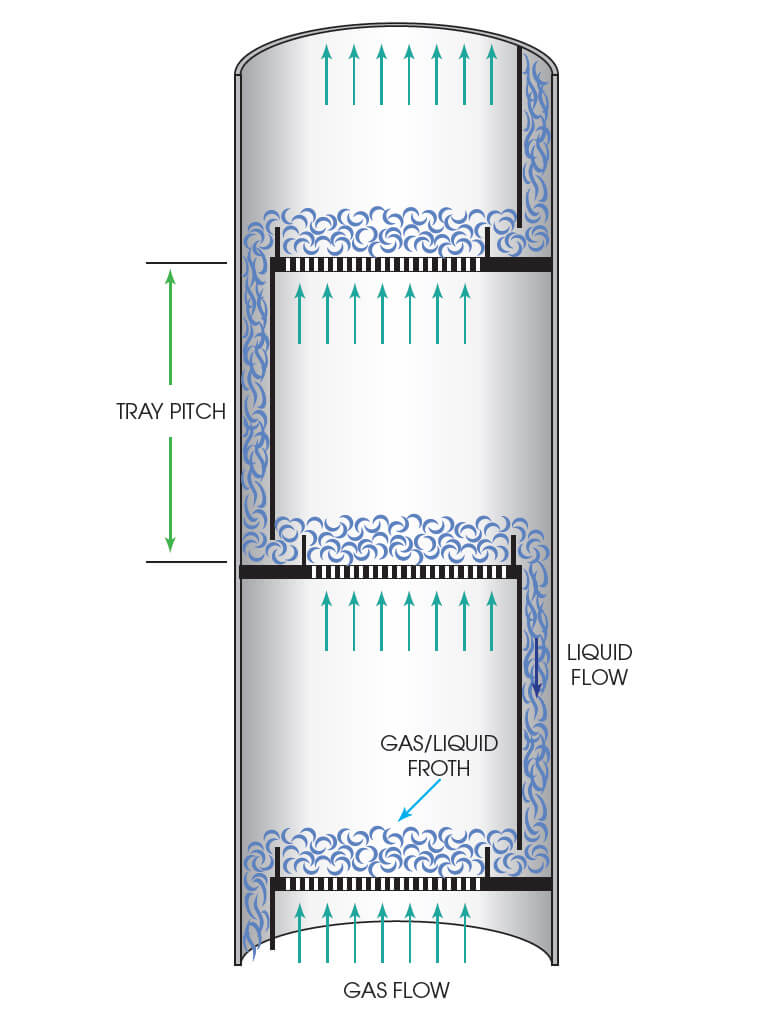

Indicative Diagram of Tray Scrubber

The gas to be treated flows upwards through each tray stage, passing through the orifices on each tray plate and then as bubbles through the scrubbing liquor on top of each tray. The scrubbing liquid flow across each tray, over the weir and down the downcomer to the tray stage below. For high efficiency scrubbing, more tray stages are added. Access for maintenance/cleaning is provided between each tray stage. Further information is available in the product brochure.Tray Selection

The materials of construction and tray design are matched to each application. It is typical for example, to use stainless steel trays with plastic or GRP vessels to give additional robustness.

Tray Towers

Tray towers are used for cleaning gas flows which are contaminated with both particulate and soluble noxious gases. Their unique design enables them to capture particulate >2 micron as well as soluble gases to high efficiencies of removal. ERG designs and manufactures each tray scrubber to meet your specific application and detailed requirements.Key Advantages of Tray Scrubbing Are:

- Multiple tray stages of scrubbing give excellent efficiencies of removal

- Highly effective at treating large gas flows at comparatively low capital cost

- Running costs are relatively low due to the low gas side pressure drop and the low liquor rates required

- Trays are self-cleaning, reliable and robust

- Trays types such as fixed valve design can be matched to suit the application

- Tray weir height can be adjusted to give enhanced capture of contamination and greater turn down if this is required

Design Parameters

- Flowrates from 2,000 to 100,000 m3/hr per tower, multiple cylindrical towers in parallel or rectangular cross-section for higher flowrates

- Removal of any soluble gaseous contaminant and soluble or insoluble particulate >2 micron

- Gaseous contaminant loadings typically from 100 to 10,000 mg/m3; particulate loadings typically up to 5,000 mg/m3

- Removal efficiencies typically 90-95% and up to 99% as required

- Vessel diameters from 600 to 3,800 mm; vessel heights typically up to 12 m

Key Features

- ERG supplies complete systems including recirculation pumps, pipework, fans, ductwork, access platform, instrumentation and control system. They can also be integrated with other ERG mass/heat transfer equipment (e.g. quench, venturi, packed tower, carbon filter, etc.) into a single air pollution control solution

- Trays used include simple perforated plates and impaction valve designs

- Adjustable weirs provide variable pressure drop and stage efficiency; under-tray sprays improve resistance to fouling

- Recirculated liquor flowrate selected to minimise pump flow and energy consumption at optimal scrubbing performance

- Droplet elimination using chevron, impaction blade or woven mesh design to suit application – clean-in-place sprays available to assist with on-line maintenance

- Scrubber sump tank integrated into the vessel – cone and sloping base designs are available to improve maintainability in solid-laden applications

- Chemical dosing, water make-up and blowdown control matched to the performance requirements

- Side-stream settler and dewatering of captured solids available if required

- Instrumentation selection to give robust operation, high reliability and tight performance control

- System control by stand-alone MCC/C&I panel or integrated DCS, with HART or Profibus protocols available as standard

- Vessels designed as standard to PD 5500 (metal) and BS EN 13121 or BS 4994 (plastic/GRP) with CE marking to PED as appropriate. Other design codes available as required

- Materials selection to suit contaminants and reaction chemistry: common materials include uPVC, PP, cPVC, derakane GRP, crystic GRP, 304SS, 316SS

Indicative Diagram of Tray Scrubber

The gas to be treated flows upwards through each tray stage, passing through the orifices on each tray plate and then as bubbles through the scrubbing liquor on top of each tray. The scrubbing liquid flow across each tray, over the weir and down the downcomer to the tray stage below. For high efficiency scrubbing, more tray stages are added. Access for maintenance/cleaning is provided between each tray stage. Further information is available in the product brochure.

Tray Selection

The materials of construction and tray design are matched to each application. It is typical for example, to use stainless steel trays with plastic or GRP vessels to give additional robustness.

UK office: +44 1403 290 000 Middle East office: +962 6515 9021 Email: info@ergapc.co.uk

ENQUIRE HERE