Sub Coolers

Sub-coolers are used to cool saturated gas streams to reduce their temperature and condense out water vapour from the gas. They are frequently used in combination with quench vessels and as part of an abatement package to condition the gas for subsequent treatment stages or simply to reduce the visual impact of the vapour plume at the stack.

Operating principle

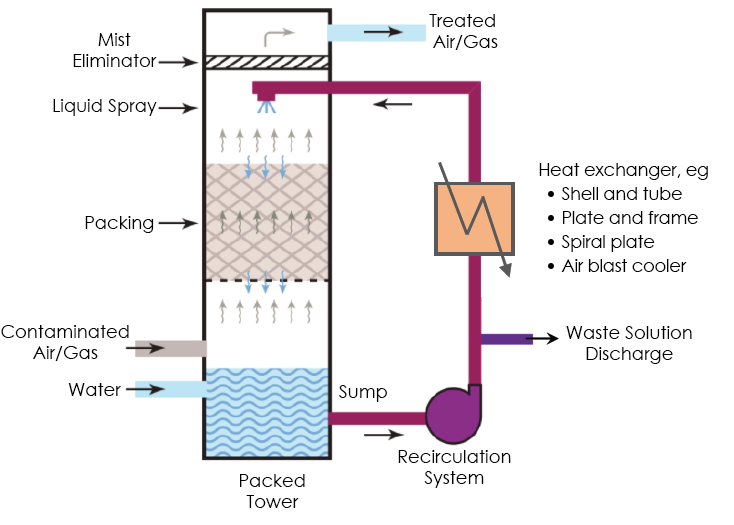

Sub-cooling can be carried out using a packed tower (the usual configuration) or with a tray tower or V-tex®.

The hot gas is cooled by direct contact with colder liquor, usually in a counter-current configuration. The colder liquor absorbs energy from the gas, thereby cooling it – and in turn the liquor temperature increases. The energy is then removed from the liquor by passing it through a heat exchanger. As the gas temperature is reduced, this also condenses water vapour from the gas stream, and so the absolute humidity (ie the kg of water vapour per kg of dry gas) of the gas is reduced.

The heat exchanger configuration depends upon the type of scrubbing liquor being used, the available cooling utility and the amount of sub-cooling required.

It is also common to combine sub-cooling and scrubbing within the same vessel.

Diagram: Sub-Cooler Arrangement

Applications

Sub-cooling is used wherever the gas temperature needs to be reduced. This is usually either

- to cool the gas and the scrubbing liquid because the scrubbing process operates more efficiently at lower temperatures due to the vapour pressure or solubility of the contaminant being removed, or

- to remove water vapour from the gas because the downstream processes require a drier gas.

ERG has extensive experience of this technology – a selection of examples are:

- Increasing the SO2 scrubbing efficiency of flue gas abatement

- Condensing water from biogas or syngas to assist the downstream compressor or gas engine

- Improving the performance of odour scrubbers by condensing VOCs

- Reducing the water content of the gas prior to reheating for activated carbon filter polishing

- Removing the heat of reaction from the scrubbing liquor for chlorine-caustic scrubbing

Design Features

- Choice of heat exchanger – Most applications use a plate and frame heat exchanger with cooling water as the cooling utility. This is usually the most cost-effective solution. However, options are available such as:

- Shell and tube or spiral plate heat exchanger – for applications where the scrubbing liquor is contaminated by solids and/or tars and so a simple plate heat exchanger would foul.

- Air blast cooler – for applications where there is no cooling water or chilled water available. The air blast cooler may be installed directly within the sub-cooler liquor circuit, or indirectly in a closed cooling loop to provide cooling water to the sub-cooler heat exchanger.

- Choice of cooling utility – Cooling water is typically the preferred utility for sites where it is available. However, where an especially cold outlet process gas temperature is required, chilled water can be used instead of or in combination with cooling water.

- Blowdown control and water balance – Sub-cooling the process gas condenses water and this needs to be properly controlled. This condensate if typically contaminated and needs to be treated as an effluent. In some applications however, it is possible to arrange the effluent blowdown from the sub-cooler as the water make-up (addition) to the upstream quench, and so minimise both process water and effluent treatment demands from the abatement package.

ERG sub-coolers are provided as part of complete scrubbing packages, with the necessary sump tank, pump, heat exchanger, pipework, fan, ductwork and controls. In the majority of applications, the sub-cooler is combined with other ERG heat and mass transfer equipment (quench, venturi, tray tower, packed tower, V-tex® scrubber, etc).

Refer to our other mass transfer technologies for full details of the range.

Sub Coolers

Sub-coolers are used to cool saturated gas streams to reduce their temperature and condense out water vapour from the gas. They are frequently used in combination with quench vessels and as part of an abatement package to condition the gas for subsequent treatment stages or simply to reduce the visual impact of the vapour plume at the stack.

Operating principle

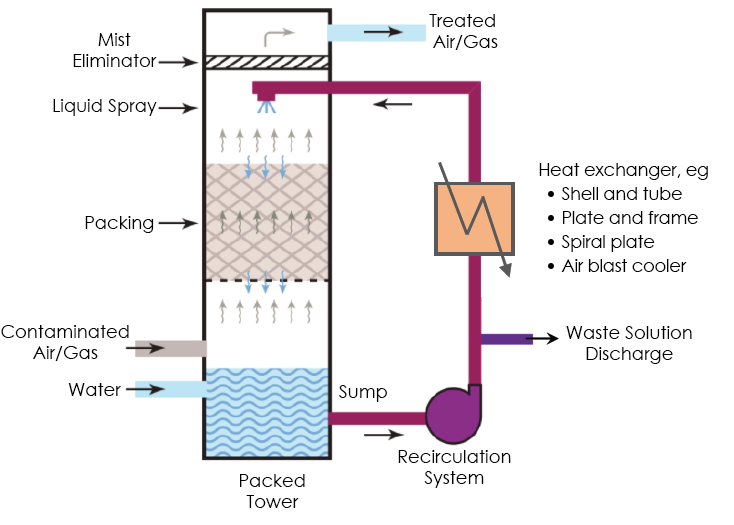

Sub-cooling can be carried out using a packed tower (the usual configuration) or with a tray tower or V-tex®.

The hot gas is cooled by direct contact with colder liquor, usually in a counter-current configuration. The colder liquor absorbs energy from the gas, thereby cooling it – and in turn the liquor temperature increases. The energy is then removed from the liquor by passing it through a heat exchanger. As the gas temperature is reduced, this also condenses water vapour from the gas stream, and so the absolute humidity (ie the kg of water vapour per kg of dry gas) of the gas is reduced.

The heat exchanger configuration depends upon the type of scrubbing liquor being used, the available cooling utility and the amount of sub-cooling required.

It is also common to combine sub-cooling and scrubbing within the same vessel.

Diagram: Sub-Cooler Arrangement

Applications

Sub-cooling is used wherever the gas temperature needs to be reduced. This is usually either

- to cool the gas and the scrubbing liquid because the scrubbing process operates more efficiently at lower temperatures due to the vapour pressure or solubility of the contaminant being removed, or

- to remove water vapour from the gas because the downstream processes require a drier gas.

ERG has extensive experience of this technology – a selection of examples are:

- Increasing the SO2 scrubbing efficiency of flue gas abatement

- Condensing water from biogas or syngas to assist the downstream compressor or gas engine

- Improving the performance of odour scrubbers by condensing VOCs

- Reducing the water content of the gas prior to reheating for activated carbon filter polishing

- Removing the heat of reaction from the scrubbing liquor for chlorine-caustic scrubbing

Design Features

- Choice of heat exchanger – Most applications use a plate and frame heat exchanger with cooling water as the cooling utility. This is usually the most cost-effective solution. However, options are available such as:

- Shell and tube or spiral plate heat exchanger – for applications where the scrubbing liquor is contaminated by solids and/or tars and so a simple plate heat exchanger would foul.

- Air blast cooler – for applications where there is no cooling water or chilled water available. The air blast cooler may be installed directly within the sub-cooler liquor circuit, or indirectly in a closed cooling loop to provide cooling water to the sub-cooler heat exchanger.

- Choice of cooling utility – Cooling water is typically the preferred utility for sites where it is available. However, where an especially cold outlet process gas temperature is required, chilled water can be used instead of or in combination with cooling water.

- Blowdown control and water balance – Sub-cooling the process gas condenses water and this needs to be properly controlled. This condensate if typically contaminated and needs to be treated as an effluent. In some applications however, it is possible to arrange the effluent blowdown from the sub-cooler as the water make-up (addition) to the upstream quench, and so minimise both process water and effluent treatment demands from the abatement package.

ERG sub-coolers are provided as part of complete scrubbing packages, with the necessary sump tank, pump, heat exchanger, pipework, fan, ductwork and controls. In the majority of applications, the sub-cooler is combined with other ERG heat and mass transfer equipment (quench, venturi, tray tower, packed tower, V-tex® scrubber, etc).

Refer to our other mass transfer technologies for full details of the range.