How V-tex® Technology Works

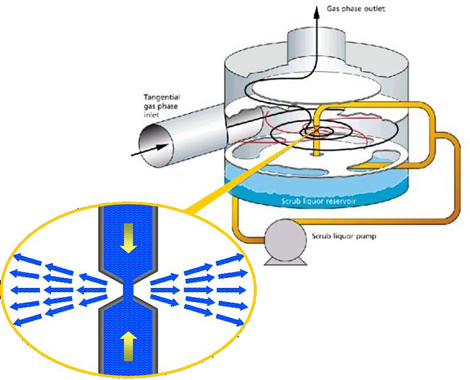

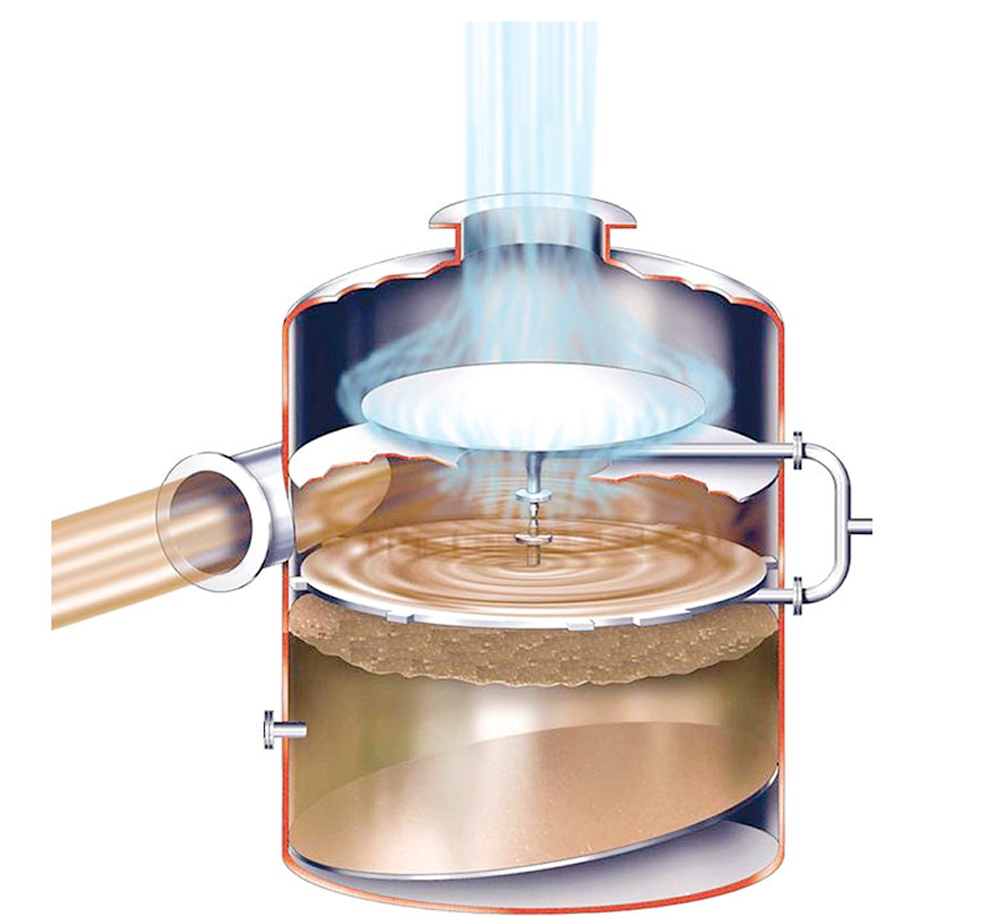

V-tex® Operating Principle

The scrubber vessel itself is an empty cylindrical chamber. The foul gas is fed into the chamber tangentially, setting up a vortex flow motion as it circulates inside the vessel.

The scrubbing liquor is fed into the heart of the gas vortex via an opposed jet nozzle which create a 360o array of fine droplets. High intensity mixing of the gas and scrub liquor droplets takes place in the vortex, setting up the conditions for highly efficient mass transfer between the gas and the scrubbing liquor. The now dirty liquor is then “flung” to the walls of the chamber and drains into the collection sump at the bottom of the vessel.

Meanwhile, the cleaned gas exits through the roof of the chamber and entrained scrub liquor droplets are captured and returned to the bulk liquor.

Multiple stages of V-tex® scrubbing can be stacked on top of one another in series in a single vessel to give extremely high efficiency scrubbing.

How V-tex® Technology Works

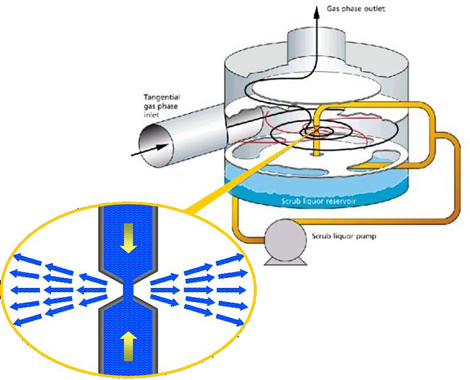

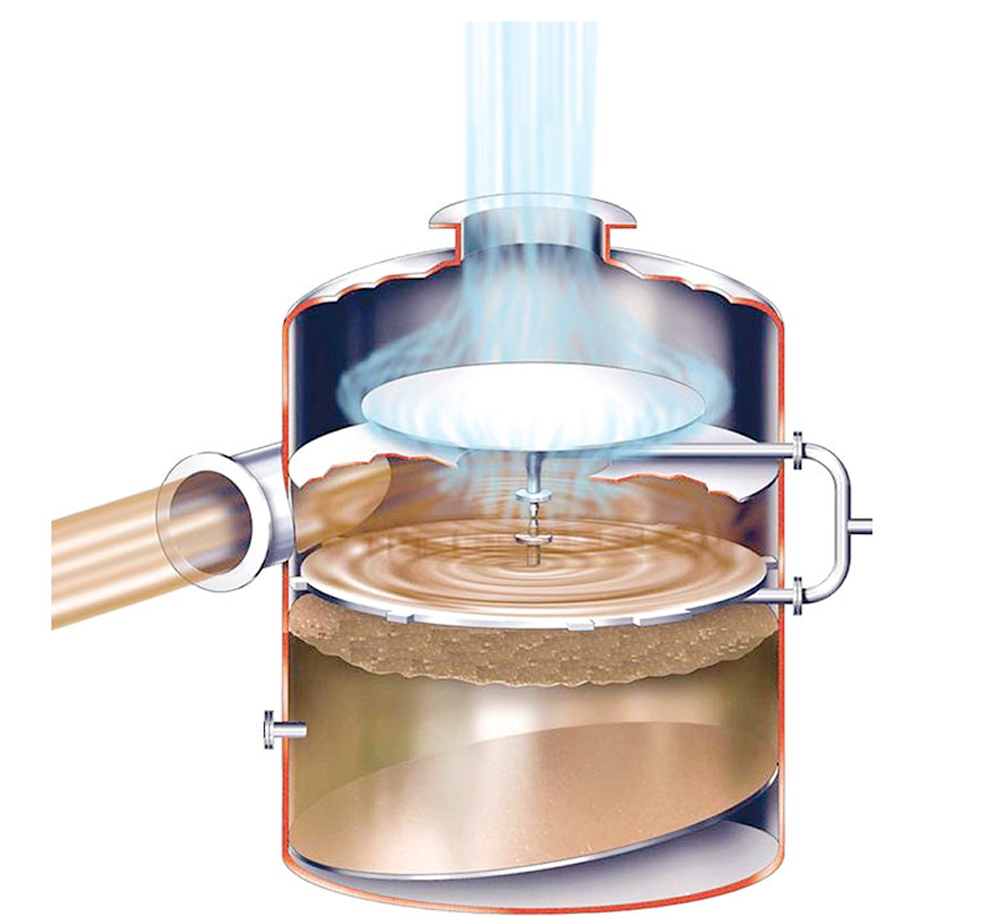

V-tex® Operating Principle

The scrubber vessel itself is an empty cylindrical chamber. The foul gas is fed into the chamber tangentially, setting up a vortex flow motion as it circulates inside the vessel.

The scrubbing liquor is fed into the heart of the gas vortex via an opposed jet nozzle which create a 360o array of fine droplets. High intensity mixing of the gas and scrub liquor droplets takes place in the vortex, setting up the conditions for highly efficient mass transfer between the gas and the scrubbing liquor. The now dirty liquor is then “flung” to the walls of the chamber and drains into the collection sump at the bottom of the vessel.

Meanwhile, the cleaned gas exits through the roof of the chamber and entrained scrub liquor droplets are captured and returned to the bulk liquor.

Multiple stages of V-tex® scrubbing can be stacked on top of one another in series in a single vessel to give extremely high efficiency scrubbing.