De NOx Systems

Nitrogen oxides are formed in combustion and also during some reactions involving metals and acids. The treatment approach used depends on the gas temperature, the NOx concentration and the relative proportions of the different nitrogen oxides (NO, NO2, N2O4, N2O2, N2O3 etc) present.

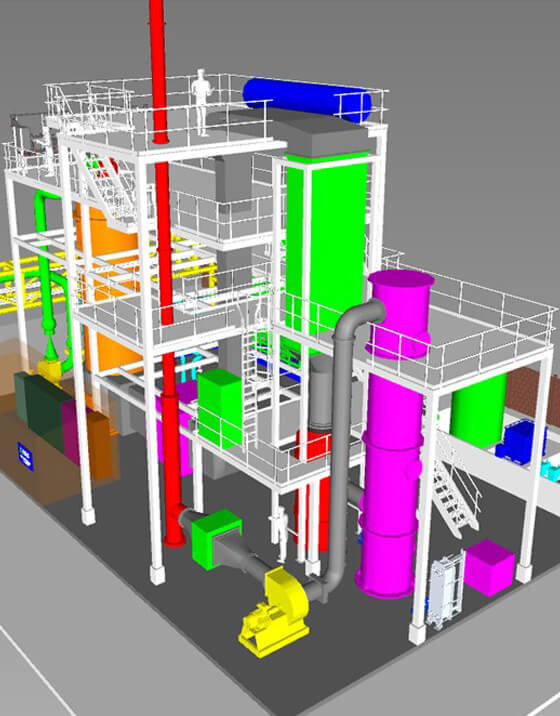

Through partner companies, we can offer de-NOx systems to the process industries as follows:

- High temperature NOx abatement using SCR (Selective Catalytic Reduction) or SNCR (Selective Non-Catalytic Reduction) technology to suit the application

- Low temperature (less than 60oC) NOx abatement using gas-phase oxidation and multi-stage scrubbing

Low temperature NOx abatement

It is well known that NO is not especially soluble and NO2 can be reduced in the scrubbing liquor to form NO which is then released from the scrubbing solution back into the gas stream, limiting the stage capture efficiency. ERG can offer treatment of chemically generated NOx using a combination of gas-phase oxidation using ClO2 or ozone, followed by multi-stage scrubbing. And by employing V-tex® technology, it is possible to generate an effluent stream from the process of sufficiently high concentration salts (NaNO2) to make it suitable for recycling and re-use in the client’s process.

See our application brochure or talk to our process sales team about how we can help.

De NOx Systems

Nitrogen oxides are formed in combustion and also during some reactions involving metals and acids. The treatment approach used depends on the gas temperature, the NOx concentration and the relative proportions of the different nitrogen oxides (NO, NO2, N2O4, N2O2, N2O3 etc) present.

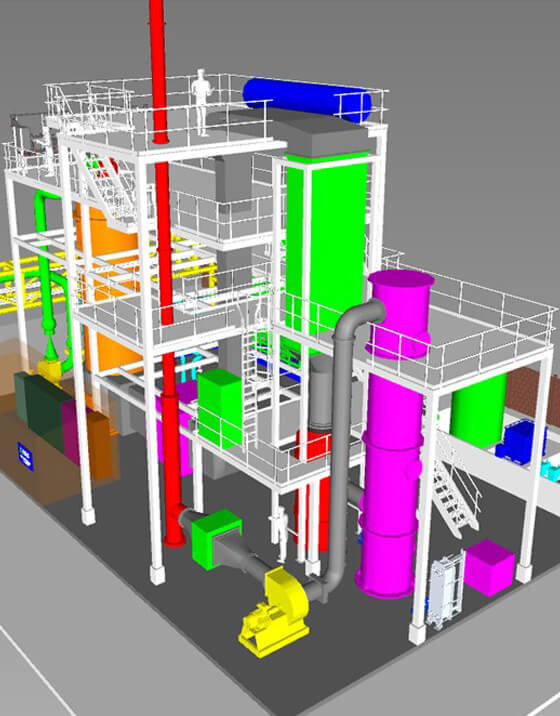

Through partner companies, we can offer de-NOx systems to the process industries as follows:

- High temperature NOx abatement using SCR (Selective Catalytic Reduction) or SNCR (Selective Non-Catalytic Reduction) technology to suit the application

- Low temperature (less than 60oC) NOx abatement using gas-phase oxidation and multi-stage scrubbing

Low temperature NOx abatement

It is well known that NO is not especially soluble and NO2 can be reduced in the scrubbing liquor to form NO which is then released from the scrubbing solution back into the gas stream, limiting the stage capture efficiency. ERG can offer treatment of chemically generated NOx using a combination of gas-phase oxidation using ClO2 or ozone, followed by multi-stage scrubbing. And by employing V-tex® technology, it is possible to generate an effluent stream from the process of sufficiently high concentration salts (NaNO2) to make it suitable for recycling and re-use in the client’s process.

See our application brochure or talk to our process sales team about how we can help.