Technology Sector Manufacturing Gas Cleaning

ERG provides a wide variety of air pollution control systems for microelectronic, speciality gases and optical fibres manufacturing plants. ERG’s purpose-designed gas cleaning systems are engineered to suit each application and supplied with a process guarantee.

Applications

ERG’s abatement packages are typically installed to treat vents from storage tanks, CVD machines, LEV vent lines. In many cases, a skid-mounted scrubber package is required, though ERG can also arrange site installation and commissioning.

Typical contaminants which we treat include:

- Acid gases – HF, F2, HCl, Cl2, HBr, Br2, COS, HCN, SO2

- Basic gases – NH3, etc

- Silicates – SiO2, H2SiF6, SiF4, SiCl4, etc

- Dust and aerosols – 100 to <1 micron particle sizes – mechanically and chemically generated

- VOCs – MEK, nMP, ethyl acetate, etc

ERG has particular experience treating halogenated semi-metals (BCl3, SiCl4, SiF4, etc) where difficult to handle gelatinous or solid precipitates form on contact with the scrubbing liquor, leading to potential for system blockage.

Technologies

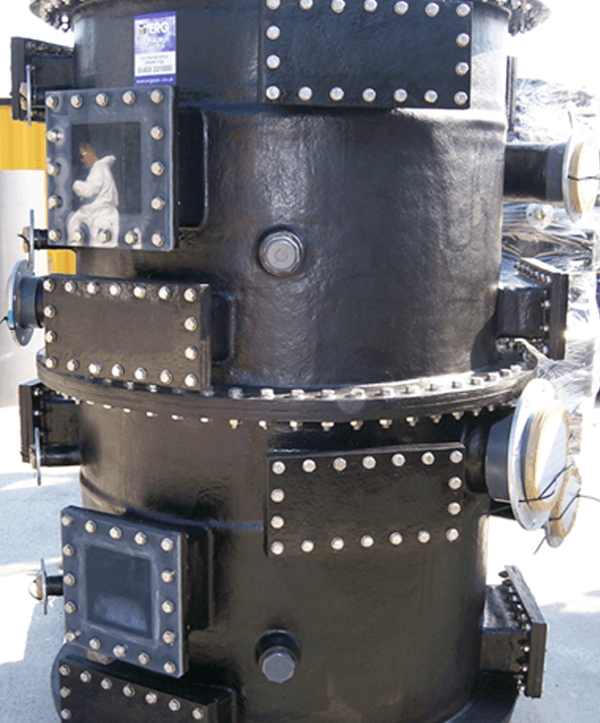

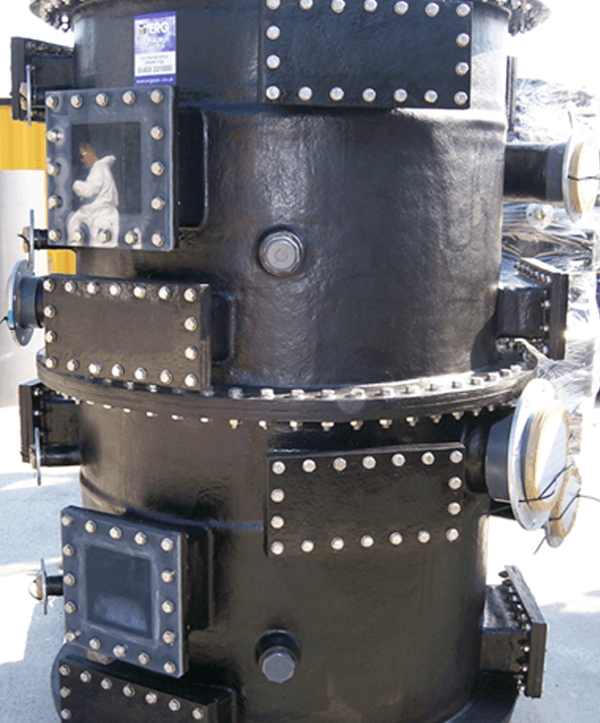

Our vent abatement systems are based on one or more of the following technologies. Each package is bespoke: designed and manufactured to the specific project requirements.

- V-tex® scrubbers – for acid gases, some dusts, some VOCs – especially for applications where clogging is a possibility

- Packed tower scrubbers – for acid gases, basic gases, some dusts, some VOCs

- Venturi scrubbers – for high concentration or fine (sub-micron) dust

- Carbon filters – for VOCs and solvent abatement

- Quench systems – for adiabatically cooling high temperature gas for further wet scrubbing

- Thermal oxidation – waste solvents and VOC-rich vent gases

Meeting Exacting Specifications

ERG’s design and project management teams are highly experienced at delivering packaged plant which meets the Tech Sector’s needs.

- All design and procurement is managed according to our ISO 9001 procedures

- All manufacturing and assembly is to the agreed codes and project specifications, managed through and certified against the project Quality and Inspection & Test Plans.

- All equipment is fully certified and documented in accordance with applicable European Standards, and CE marked accordingly.

- Vessels can be supplied to BS EN 13121, PD 5500 or ASME VIII as appropriate, and packages CE marked to the Pressure Equipment (2014/68/EU) and ATEX (2014/34/EU) Directives depending on the specification requirements.

Choice of Materials

Every ERG package has materials selected to match the specification. All systems are mechanically designed for the operating and design pressures and temperatures. Common materials include plastics, GRPs and Stainless Steels.

ERG Package Scope of Supply

ERG is a specialised scrubbing supplier. Our typical scope includes:

- Project management including customer design reviews, progress reporting, equipment interface agreement, programme management, site activities co-ordination, documentation packages

- Process design and technical submission – heat & mass balance, P&ID, control philosophy, technical schedules

- Detailed mechanical and electrical design – model and/or package General Arrangement drawings, civils requirements, site wiring details, interface details, off-loading and installation details

- Sub-supplier procurement, quality assurance and expediting – vessels, pipework & valves, pumps, fans, heat exchangers, instrumentation, control panels or local JBs, access steelwork, pressure protection devices

- Package assembly including full pipework and wiring, factory testing, certification

- Delivery

- Installation and commissioning are also available if required – phone support during this phase can be arranged if preferred

Plastic and GRP vessels are manufactured by ERG’s sister company ERG (Plastic Fabrication) Ltd and skid assembly and testing are managed at our facility in West Sussex.

Operational Peace of Mind

- Every ERG abatement package carries a performance guarantee – as an operator you can be sure the equipment will meet the process requirements

- Our standard (12 months) or extended warranty guarantees the mechanical and electrical parts against defects

- And our Maintenance department can assist with routine, shut-down or emergency maintenance

Our Clients

Contracts can be placed direct by the site owners, although we frequently work through main contractors.

Technology Sector Manufacturing Gas Cleaning

ERG provides a wide variety of air pollution control systems for microelectronic, speciality gases and optical fibres manufacturing plants. ERG’s purpose-designed gas cleaning systems are engineered to suit each application and supplied with a process guarantee.

Applications

ERG’s abatement packages are typically installed to treat vents from storage tanks, CVD machines, LEV vent lines. In many cases, a skid-mounted scrubber package is required, though ERG can also arrange site installation and commissioning.

Typical contaminants which we treat include:

- Acid gases – HF, F2, HCl, Cl2, HBr, Br2, COS, HCN, SO2

- Basic gases – NH3, etc

- Silicates – SiO2, H2SiF6, SiF4, SiCl4, etc

- Dust and aerosols – 100 to <1 micron particle sizes – mechanically and chemically generated

- VOCs – MEK, nMP, ethyl acetate, etc

ERG has particular experience treating halogenated semi-metals (BCl3, SiCl4, SiF4, etc) where difficult to handle gelatinous or solid precipitates form on contact with the scrubbing liquor, leading to potential for system blockage.

Technologies

Our vent abatement systems are based on one or more of the following technologies. Each package is bespoke: designed and manufactured to the specific project requirements.

- V-tex® scrubbers – for acid gases, some dusts, some VOCs – especially for applications where clogging is a possibility

- Packed tower scrubbers – for acid gases, basic gases, some dusts, some VOCs

- Venturi scrubbers – for high concentration or fine (sub-micron) dust

- Carbon filters – for VOCs and solvent abatement

- Quench systems – for adiabatically cooling high temperature gas for further wet scrubbing

- Thermal oxidation – waste solvents and VOC-rich vent gases

Meeting Exacting Specifications

ERG’s design and project management teams are highly experienced at delivering packaged plant which meets the Tech Sector’s needs.

- All design and procurement is managed according to our ISO 9001 procedures

- All manufacturing and assembly is to the agreed codes and project specifications, managed through and certified against the project Quality and Inspection & Test Plans.

- All equipment is fully certified and documented in accordance with applicable European Standards, and CE marked accordingly.

- Vessels can be supplied to BS EN 13121, PD 5500 or ASME VIII as appropriate, and packages CE marked to the Pressure Equipment (2014/68/EU) and ATEX (2014/34/EU) Directives depending on the specification requirements.

Choice of Materials

Every ERG package has materials selected to match the specification. All systems are mechanically designed for the operating and design pressures and temperatures. Common materials include plastics, GRPs and Stainless Steels.

ERG Package Scope of Supply

ERG is a specialised scrubbing supplier. Our typical scope includes:

- Project management including customer design reviews, progress reporting, equipment interface agreement, programme management, site activities co-ordination, documentation packages

- Process design and technical submission – heat & mass balance, P&ID, control philosophy, technical schedules

- Detailed mechanical and electrical design – model and/or package General Arrangement drawings, civils requirements, site wiring details, interface details, off-loading and installation details

- Sub-supplier procurement, quality assurance and expediting – vessels, pipework & valves, pumps, fans, heat exchangers, instrumentation, control panels or local JBs, access steelwork, pressure protection devices

- Package assembly including full pipework and wiring, factory testing, certification

- Delivery

- Installation and commissioning are also available if required – phone support during this phase can be arranged if preferred

Plastic and GRP vessels are manufactured by ERG’s sister company ERG (Plastic Fabrication) Ltd and skid assembly and testing are managed at our facility in West Sussex.

Operational Peace of Mind

- Every ERG abatement package carries a performance guarantee – as an operator you can be sure the equipment will meet the process requirements

- Our standard (12 months) or extended warranty guarantees the mechanical and electrical parts against defects

- And our Maintenance department can assist with routine, shut-down or emergency maintenance

Our Clients

Contracts can be placed direct by the site owners, although we frequently work through main contractors.